Product Details

Certification: CE / ISO / FDA / SGS / TUV

Payment & Shipping Terms:

Minimum Order Quantity: 1

Price: Negotiable

Packaging Details: Wooden case

Delivery Time: 15 workingdays

Payment Terms: T/T, L/C, Western Union

Supply Ability: 2000 units

Detailed Product Description

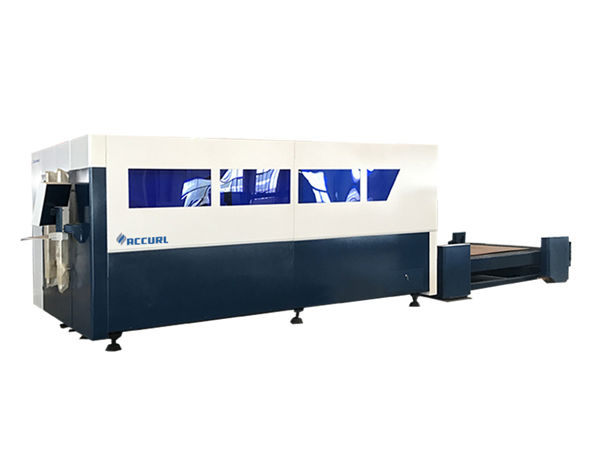

| Product Name: | Fiber Laser Cutting Machine | Laser Type: | Fiber Laser |

|---|---|---|---|

| Laser Power: | 500-1000w | Working Area: | 1500*3000mm |

| Laser Wavelength: | 1070-1090nm | Power Supply: | 380V/50Hz |

| Warranty: | 1 Year | Cutting Head: | Raytools |

Main configuration and technical advantage

Little to no maintenance costs

Parts process cost is very low

A "clean cut" surface quality is obtained

Fiber laser cutting is the fastest process for thin sheet metal

Reflective materials like aluminium,copper and brass can be cut with ease

Resonator life is over 100,000 working hours

Main Features

1.High stability: the world's top imported fiber laser, stable performance and service life of critical component up to 100,000 hours;

2. Fast cutting speed save working time .

3. Energy saving and environmental protection;

4. Excellent quality of light beam:small focus facula, fine cutting line, high working efficiency,best processing quality.

5.Very low maintenance costs: optical fiber transmission, without reflection lens; can save a lot of maintenance costs;

6. Products easy operation : no need to adjust the optical path;

7. Flexible light guide effect: small size, compact structure and easy to meet flexible manufacturing requirements.

Technical Parameters

| Product name | Fiber Laser Cutting Machine |

| Laser Type | Fiber Laser |

| Working area(mm) | 1300*2500MM/1500*3000MM |

| Cutting Head | Raytools Auto-Focus (Swiss) |

| Laser power(W) | 500W/800W/1000W/1500W |

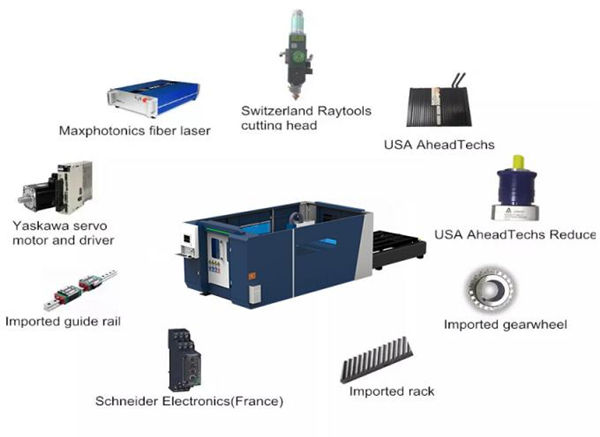

| Driving and Transmission Way | Servo Motor ,Gear Rack, Linear Guide Rail |

| Max running speed | 600m/min |

| Positioning Accuracy | ≤±0.05mm |

| Re-positioning Accuracy | ≤±0.03mm |

| Working Power Supply | AC220V±10% 50HZ/380V 50Hz |

| Working Table | Rack working platform |

| Control System | Cypcut control system |

| Location System | Red dot indicator |

| Water Cooling System | CW6300 Constant temperature water chiller |

| Max Acceleration | 1G |

| Formats | BMP,DXF,PLT,DST,CDR,GPEG |

| Cutting Depth | According the power |

| Whole machine weight | 2800KG |

| Transmission | Precise pinion and rack,dual-drive transmitting |

| Descriptions | Parameters | |

| Model | 1530 Fiber laser cutting machine | |

| Working Area | 1500*3000mm | |

| Laser Power | 500W,1000W,15000W,2KW,3KW and so on, it depends on your demand. | |

| Laser Wave Length | 1064nm | |

| Working Table | Sawtooth | |

| Maximum Idle Running Speed | 1200mm/s | |

| Position Accuracy | ±0.05mm/m | |

| Position Speed | 20m/min | |

| Minimum Line Width | ± 0.02mm | |

| Cutting Thickness | 0-12mm | |

| Control System | Cypcut | |

| Position Type | red dot | |

| Power Consumption | ≤12KW | |

| Working Voltage | 380V/50Hz | |

| Auxiliary Gas | oxygen,nitrogen,air | |

| Working life of fiber module | More than 100000 hours | |

| Fiber laser cutting head | Lasermech made in USA | |

| Focus lens | Lasermech made in USA | |

| Driver system | 1500W Fuji servo motor made in Japan | |

| Liner guider system | PMI made in Taiwan , (Option THK made in Japan) | |

| Transmit system | Dual Rack & Pinion type | |

| Rack system | made in Germany | |

| Chain system | Igus made in Germany | |

| Delivery time | 15 days |

Product Application

1.Adopting advanced fiber laser generator and ball screw moving system, it can cut and punch different kinds of metal material with high precision and high speed.

2.Since laser is transmitted by fiber, it is no need to maintenance or adjust the laser optical path. It greatly reduces the machines fault rate and prolongs the working life.

3.Large format cutting area meets the demands of various kinds of metal processing.1.Adopting advanced fiber laser generator and ball screw moving system, it can cut and punch different kinds of metal material with high precision and high speed.

Applications

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing .