Product Details

Certification: CE / ISO / FDA / SGS / TUV

Payment & Shipping Terms:

Minimum Order Quantity: 1

Price: Negotiable

Packaging Details: Wooden case

Delivery Time: 15 workingdays

Payment Terms: T/T, L/C, Western Union

Supply Ability: 2000 units

Detailed Product Description

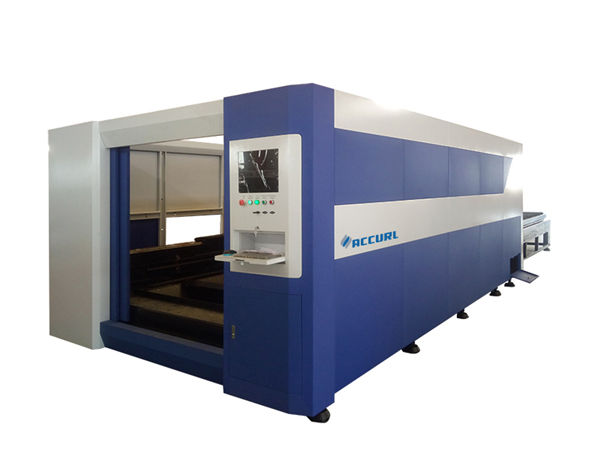

| Product Name: | Fiber Laser Cutting Machine | Laser Type: | Fiber Laser |

|---|---|---|---|

| Laser Power: | 500-1000w | Working Area: | 1500*3000mm |

| Laser Wavelength: | 1070-1090nm | Power Supply: | 380V/50Hz |

| Warranty: | 1 Year |

Main configuration and technical advantage

1, Fiber laser cutting is the fastest process for thin sheet metal.

2, A "clean cut" surface quality is obtained.

3, Reflective materials like aluminium,copper and brass can be cut with ease.

4, Parts process cost is very low.

5, Little to no maintenance costs.

6, Consumable part cost is low. The only parts that need to be changed are nozzles, ceramics and protection glasses over long periods. There are no other consumable costs.

7. Resonator life is over 100,000 working hours

Main Features

1, Excellent beam quality: smaller focused spot make more efficient work and cutting quality.

2, High cutting speed: its speed is twice of the same CO2 tube laser cutting machine

3, High stability: the world’s top fiber laser generator makes stable performance, and the key components of the machine owns the life of up to 100,000 hours

4, High electro-optical conversion efficiency: fiber laser is three times higher than CO2 laser and saving energy

5, Low use-cost: whole machine consume less energy, only 20%-30% of traditional CO2 laser machine

6, Low using cost: no laser working gas, it is by fiber optic transmission, without lens reflecting, can save a lot of maintenance costs

7, Smart operation and easy maintenance: optical fiber transmission, no need to adjust the optical path

8, Super flexible light guide effect: compact structure, satisfies flexible processing requirements

Main Configuration

| Item | Name | Quantity | Brand |

| Laser | fiber laser | 1 SET | Maxphotonics |

| Cutting head | Specialized cutting head | 1 SET | RayTools BT( Switzerland) |

| Machine bed | 1 SET | China | |

| Precise Rack | 1 SET | TAIWAN DINSENSE | |

| Machine body | Precise linear guide rail | 1 SET | TAIWAN HIWIN/ TAIWAN shac |

| X,Y axis servo and driver | 1 SET | LETRO | |

| Reducer system | 1 SET | TAIWAN DINSENSE | |

| controller | 1 SET | FRANCE Schneider | |

| Machine bed accessories | 1 SET | CHINA | |

| Digital cutting system | Controller system | 1 SET | Shanghai cypcut /Shanghai Empower |

| Chiller | 1 SET | Teyu | |

| Water recycling equipment | 1 SET | China |

Technical Parameters

| Model | 3015 |

| Laser Working Medium | ND:YVO4 |

| Laser Wavelength | 1070nm |

| Power | 500W/800W/1000W |

| Beam Quality | <0.373mrad |

| Max cutting thickness | Depends on power |

| Working area | 3000mm×1500mm |

| Positioning Accuracy | ≤±0.05㎜/m |

| Repeatition Accuracy | ≤±0.05㎜/m |

| Power Supply | 380V/50Hz |

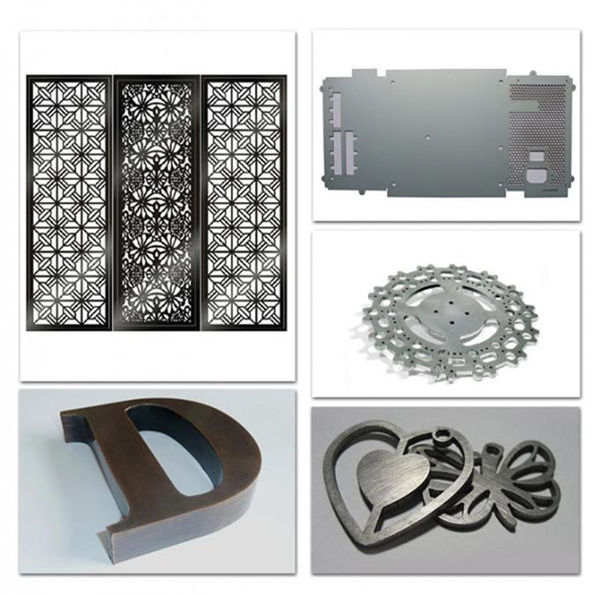

Cutting Machine Application

Widely used for cutting, welding and drilling on stainless steel, carbon steel, Alloy steel, silicon steel, galvanized steel sheet, nickel-titanium alloy, chromium-nickel alloy, titanium alloy and other metal materials.

Applied in sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automobile, food machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, sheet metal processing, kitchen utensils and appliances, craft gifts, tool processing, decoration, advertising, metal processing and other manufacturing industries.

A. Machine will be supplied with training video and user's manual in English for installation, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone, skype….

B. We offer technician to customer's site for installation and training, customer shall cover visa, ticket, local living cost.

C. Customer may come to our factory for training. We will offer training of installation, operation, machine trouble-shooting, and maintenance.

D. We offer life-long technical service for all our machines.