Product Details

Detailed Product Description

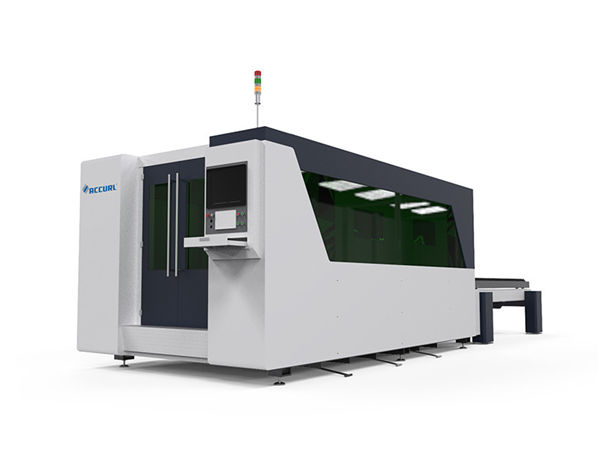

| Product Name: | 3015 Fully Covered Metal Fiber Laser Cutter With Exchange Table | Laser Power: | 1000w - 3000W |

|---|---|---|---|

| Laser Wavelength: | 1080nm | Working Area: | 3000*1500mm |

| Laser Cutter Head: | Raytools | Chiller: | S&A |

Product Desciption

Full closed protection improves using security; laser protection glass isolates laser radiation to human beings; automatic collection system of smokes and dusts is environment friendly; intelligent monitoring system reduces accident rate, making us enjoy beauty and health in cutting process.

Using flake graphite cast iron, the lowest tensile strength of which is 200MPa. High carbon content, high compressive strength and high hardness. Strong shock absorption and wear resistance. Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine accuracy could maintain for a long time, and no deformation in a life cycle.

Applicable to various focal lengths, which are controlled by machine tool control system. Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal.

Specially used for cutting 0.5-20mm carbon steel, 0.5-10mm stainless steel, 0.5-6mm brass, 0.5-10mm aluminum, 0.5-4mm copper, as well as galvanized steel, electrolytic steel and silicon steel etc.

Fiber Laser Cutting Machine Advantages

1) Fiber laser cutting is the fastest process for thin sheet metal.

2) A “clean cut” surface quality is obtained.

3) Reflective materials like aluminium,copper and brass can be cut with ease.

4) Parts process cost is very low.

5 ) Little to no maintenance costs.

6) Free you hands, Focal length is controlled by operating system. We don’t need to do manual regulation, which effectively avoids errors or faults caused by manual operation.

7) Resonator life is over 100,000 working hours.

8) Double ball screw close-loop system and imported open-type CNC system, ensure high accuracy and high working efficiency during high speed cutting.

9) After artificial aging, solution treatment and finishing, crossbeam owns good integrity, rigidity, surface quality, toughness and ductility. Aluminum alloy’s metal characteristics of light weight and strong rigidity are helpful to high speed movement in processing, and high flexibility is beneficial to high-speed cutting of various graphics based on high accuracy. Light crossbeam can give equipment a high operation speed, improving processing efficiency to ensure processing quality.

Specifications

| Laser wavelength | 1080nm |

| Cutting thickness | 0.2-16mm |

| Laser output power | 1000W |

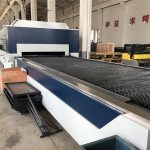

| Maximum processing range | 3000 *1500mm |

| Machine drive mode | imported rack gear and pinon drive |

| Y X. axis positioning accuracy | ±0.01mm |

| X.Y axis repeat positioning accuracy | ±0.01mm |

| Power supply mode | 380V / 50Hz |

| Maximum cutting speed | 45m/min |

| Minimum cutting line width | 0.02mm |

| Cooling mode | 3P Water cooling |

Accessories

Applications Industrial

Sheet metal processing, die - cutting board processing, electronics, electrical, aerospace, machinery, elevators, automobiles, ships, tools processing, subway accessories, oil machinery, food machinery, craft gift, decoration, advertising, metal processing and other processing industries.