Product Details

Certification: CE FDA ISO9001

Payment & Shipping Terms:

Minimum Order Quantity: 1 SET

Price: USD

Packaging Details: Wooden Box

Delivery Time: 30-45 Days

Payment Terms: D/A, D/P, L/C, Western Union, T/T, MoneyGram

Supply Ability: 100 SETS PER MONTH

Detailed Product Description

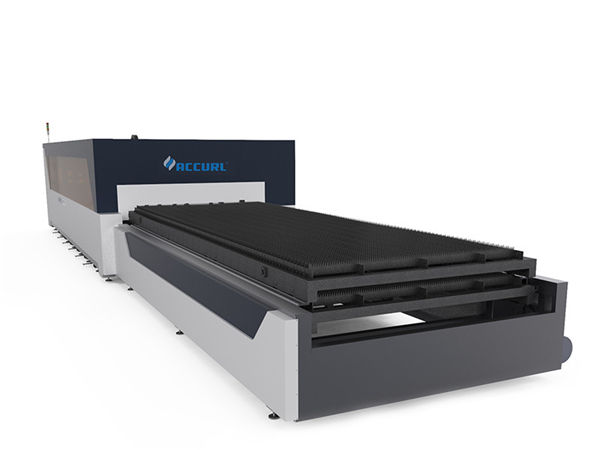

| Model NO.: | RL-PT3015-1000 | Name: | Fiber Laser Cutting Machine |

|---|---|---|---|

| Condition: | New | Guide Rails: | Taiwan Hi-Win Square Guide |

| Fiber Laser Cutting Head: | USA Lasermech | Cutting Speed: | Adjustable |

| Floor Space: | 5.6m X 3.2m | Laser Type: | Max, Raycus, IPG |

| Control System: | Professional Laser Control System--Cypcut | HS Code: | 8456110090 |

Advantages

1. Usually have 50 units of laser marking machine(Fiber, CO2, UV, Mopa) in stock, lead time 3-5 days.

2. Sold 4500 units of laser machines in China market in 2017, with reasonable price.

3. Fiber Laser cutting machine, (700W, 1000W, 1500W+ laser cutter), usually sell 30 units/month in China.

How laser cutting works

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials would involve a motion control system to follow a CNC of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Riselaser fiber laser cutting advantages

1, Cost saving on power consumption/ only 20-30% of co2 laser cutting machine under same power.

2, Flexibility and precision cutting of simple or complex parts

3, Adopts imported world brand fiber laser/Life time over 100,000hrs

4, Imported servo motor and gearing system ensure precision cutting

5, High quality cut with no extra finishing required

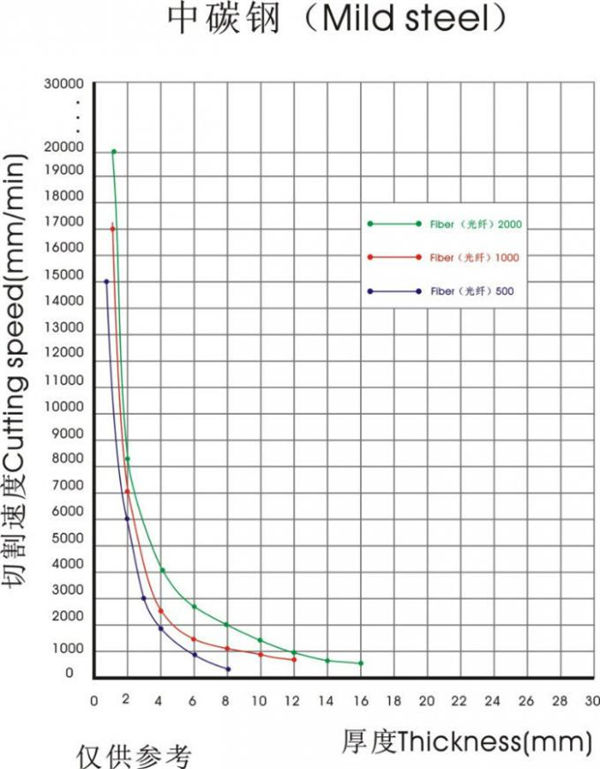

6, Higher cutting speed and efficient, speed of cutting plate over 10 meters per minute

7, Non contact cut which means no marks or contamination of the material

8, Ability to cut virtually any sheet metal

Specifications

| Medium of laser | Semiconductor pump continuous ytterbium doped fiber | |

| Laser wavelength | 1070nm | |

| Laser output power | 500W | 1000W |

| Cutting area(mm)(L×W) | 3000mm×1500mm | |

| Max cutting speed(m/min) | 18 m/min | 24 m/min |

| Min line width | < 0.1mm | < 0.125mm |

| Cutting depth | 0.2mm---5mm | 0.2mm---8mm |

| Driving Way | Imported servo motor | |

| Tranmission Way | Y-axis imported gear rack double driver,X-axis imported gear rack | |

| Operational Temp Range | 10 ~ 40ºC | |

| Electrical Requirements | 380V/50Hz.60Amp | |

| Cooling Mode | Water cooled | |

| Continuous working time | 24 hours | |

| Warranty: | 2 years on laser source | |

| Weight | About 3000kg | |

| Outline size(mm) | 4270mm×2420mm×1750mm (L×W×H) | |

Applicable Materials

Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet and other metal pipes and tubes.

Applicable Industry

It is widely applied in industrial pipeline processing, explosion-proof equipment, military industry, chemical industry, oil exploration, lamps and lanterns, metal processing, ironware, building, etc.

Fiber laser cutting samples

After-sale Service

1.One years warranty for machine, One years for domestic source (One year for IPG source)

2. Technical support

Lifelong technical support online or by email and 18 hours online service to help you use our machine well.

3. Oversea service

Offer oversea service for training,installing, operating if necessary (Buyer need offer food & accommodation, round tickets and engineer charges USD200/day)

4. Training service

Offer training at our factory for free (you could visit us and learn).