Product Details

Certification: CE

Payment & Shipping Terms:

Minimum Order Quantity: 1Set

Price: Negotiable

Packaging Details: 1*40GP container

Delivery Time: 30days

Payment Terms: L/C, D/A, T/T, D/P, Western Union

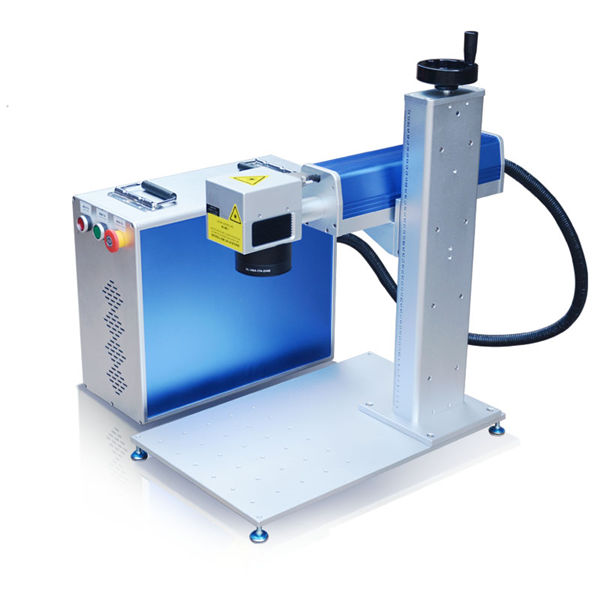

Detailed Product Description

| Application: | All Metal Material | Cutting Thickness: | Upto 1mm SS |

|---|---|---|---|

| Laser Type: | Imported Original Fiber Laser | Max Cutting Thickness: | 20mm/CS; 10mm/SS |

| Min.line Width: | 0.1mm | Control Software: | Cypcut |

| Graphic Format Supported: | AI, BMP, DST, DWG, DXF, DXP, LAS, PLT | Brand Name: | |

| Repeating Accuracy: | +/-0.03mm | Operating Temperature: | 0°C-45°C |

| Cooling Mode: | Water Cooling | Laser Source: | IPG/Nlight/Raycus/Max |

| Voltage: | AC380V±10% 50HZ(60HZ) | Cutting Area: | 3000x1500mm |

Application

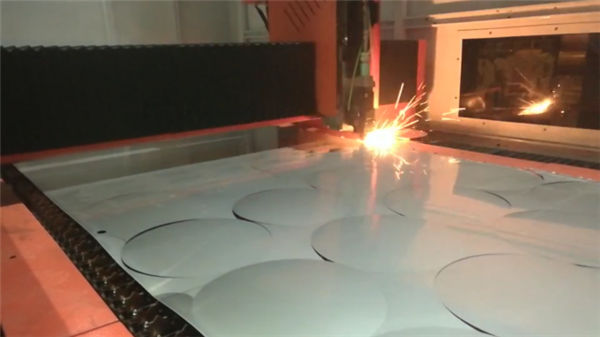

Applied for Standard Stainless steel strip with thickness 0.2 to 14mm

Product

Cut round circle 100-800mm

Project Configration

| code | Item |

| 1 | Scrap disposal system |

| 2 | Mechanical arm |

| 3 | Laser cutting machine |

| 4 | The central electric control cabinet |

| 5 | Cooling system |

| 6 | Feeding machine |

Laser Machine Spec

| Laser source medium | Fiber |

| Cutting range (L * W) | 10000 mm × 15000 mm |

| Z axle stroke | 250 mm |

| Max. positioning speed | 120 m/min |

| X,Y axle Max. accelerate speed | 1.0G |

| Cooling form | Water cooling |

| Laser wavelength | 1070nm |

| Output power of laser source

| 500W/1000W / 1500W / 2000W 2500W / 3000W / 4000W (Optional) |

| Min. cutting gap | ≤ 0.1 mm |

| Positioning accuracy of X, Y and Z axles | ± 0.03 mm |

| Repeated positioning accuracy of X, Y and Z axles | ± 0.01 mm |

| Thickness of cutting material (according to material) | 0.2 - 25 mm |

| Driver model | Imported servo motor |

| Power requirement | 380V, 50/60 Hz |

| Working temperature | 0-45℃ |

| Continuous working time | 24 Hours |

| Machine weight | About 12000 Kgs |

| Total protection level of power supply | IP54 |

Laser cutting machine parameter

The lathe bed is made of the overall welding structure, after annealing after stress relief were rough machining and the secondary vibration aging treatment of metal finishing, better solve the stress due to welding, thus greatly improve the stability of machine tool.X, Y, Z axis adopts the Japanese servo motor, equipped with high precision grinding gear reducer and rigidity rack, high precision linear guide, such as efficient transmission mechanism, effectively guarantee the accuracy of transmission;Machine is equipped with automatic lubricating device, cutting area has dust exhausting device, waste car at the bottom of the cutting area, Mechanical cutting motion, maintain arc poor filling operation, don't need to return to the origin after one time cutting travel, Thus saving a lot of time, cutting speed improved greatly. By calculation, can improve the efficiency of more than 15% of the cutting with this improvement.

Moving cutting bed’s movement control by chain driven by servo motor, the bed surface is made up of copper and aluminum cylinder cap, copper cap can reduce the scratch plate effectively, reduce the cost of replacement.

Collecting, uncoiling, Straighten, feeding device parameters

| Code | Performance | Parameter | Remark |

| 1 | maximum loading weight of the coil

| 10T(Max) | |

| 2 | Width of coil | 200mm~1300mm | |

| 3 | Thickness of coil | 0.3mm~1.5mm | |

| 4 | material roll inner diameter

| Ø460-530mm | |

| 5 | material roll outer diameter | Ø1300mm(Max) | |

| 6 | production line speed | 20m/min | |

| 7 | loading mode | loading car | |

| 8 | Tensioning method

| hydraulic distension

| |

| 9 | braking method

| Pneumatic disc brake

| |

| 10 | Feeding control

| electric induction

| |

| 11 | uncoil | frequency control

| |

| 12 | Carrier; Material with a coffret

| automatic | |

| 13 | pressing device

| Automatic | |

| 14 | Flat roller | up 11 down 12 | |

| 15 | pinch roll | 1set | |

| 16 | feeder | pinch roller | |

| 17 | Feeder driver | servo motor |

Cutting Samples: (attached photos are for reference , please contact with us for detail video)

Pre-sale service

1. Free sample cutting,

For free sample cutting/testing, please send us your CAD file, we will do cutting here and make video to show you the cutting ,or send sample to you check cutting quality.

2. Customized machine design

According to customer’s application, we may revise our machine accordingly for customer’s convenience and high production efficiency.

Service after sales

A. Machine will be supplied with training video and user's manual in English for installation, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone, skype….

B. We offer technician to customer's site for installation and training, customer shall cover visa, ticket, local living cost.

C. Customer may come to our factory for training. We will offer training of installation, operation, machine trouble-shooting, and maintenance.

During training in our workshop, we offer free training and living cost for 7 days, limit 2 people.

Warranty

a).1Year for the whole machine(Man-made Damage is negotiated.).

b).Laser source 2 Years warranty

c).Lifelong maintenance and spare parts supply

d).Free training for operation staffs. (engineer can go abroad is negotiated.)

FAQ

Q1: How can I get the best machine for me?

You can tell us your working material, detail work by picture or vedio so that we can judge whether our machine can meet your need or not. Then we can give you the best model depends on our experience.

Q2: This is the first time I use this kind of machine, is it easy to operate?

We will send you manual and guide vedio in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by "Teamviewer" online help software.Or we can talk by phone, email or other contact ways.

Q3: If the machine has problem in my place, how could I do?

We could send free parts to you in warranty period if machines have any problem under "normal use".

Q4:Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.