Product Details

Certification: ISO9001:2008

Payment & Shipping Terms:

Minimum Order Quantity: 1

Price: negotiation

Packaging Details: Wooden case

Delivery Time: 7-15 days

Supply Ability: 1 units/ month

Detailed Product Description

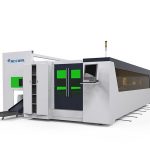

| Product Name: | Fiber Laser Cutting Machine | Laser Power: | 1000w 1500w |

|---|---|---|---|

| Laser Wavelength: | 1080nm | Working Area: | 3000*1500mm |

| Cutting Thickness: | 0-16MM (depends On Laser Power) | Power Supply: | 380v |

| Warranty: | 1 Year | Laser Type: | Fiber Laser |

Product Description

1. Low cost and the power consumption is 0.5-1.5kw/h; Customer can cut all kinds of metal sheets by blowing air;

2. High-performance. Imported the original packaged fiber laser, with stable performance and the lifespan is over 100,000 hours;

3. High speed and efficiency, the speed of cutting metal sheets close to tens of meters;

4. The laser maintenance free;

5. The cutting edge looks perfect and the appearance is smooth and beautiful;

6. Imported the transmission mechanism and servo motor, and high cutting accuracy;

7. Dedicated software enables graphic or text to be instantly designed or processed. Flexible and easy operation.

Metal Sheet Laser Cutting Machine Advantages

1. Using Plug welding process to weld machine body. First through heat treatment then do high-precision machining to mold finally. The rigidity and precision of whole machine is high and with stable performance.

2. The whole beam is firstly though heat treatment then do high precision machining to mold finally. The rigidity and precision of the whole machine is high and with stable performance.

3. Advanced high-precision dual-drive transmission system and advanced sports system to ensure a smooth and fast operation at the same time with high precision.

4. Using high efficiency dust removal system to avoid the bed,the surrounding air and environmental pollution as much as possible.

5. Control system uses imported high-end CNC system.The control system is powerful and easy to use and grasp.

6. Powerful control system and superior software combination, users can integrate their own PC software,Maximize the effectiveness of the machine.

Technical Specifications

| Laser wavelength | 1080nm |

| Cutting thickness | 0.2-16mm |

| Laser output power | 1000W |

| Maximum processing range | 3000 *1500mm |

| Machine drive mode | imported rack gear and pinon drive |

| Y X. axis positioning accuracy | ±0.01mm |

| X.Y axis repeat positioning accuracy | ±0.01mm |

| Power supply mode | 380V / 50Hz |

| Maximum cutting speed | 45m/min |

| Minimum cutting line width | 0.02mm |

| Cooling mode | 3P Water cooling |

Laser cutting machines details

Controller-Cypcut Numerical control system consists of PC control system, drive and servo motor and other major components Fiber laser cutting machine adopts CNC system,Represents the most professional laser machining CNC system. Cypcut With its good cost performance meets the requirements of customers for high performance cnc system.Support AI,DXF,PLT,etc .Gerbergraphics data format,accept Mater Cam,Type3,Words such as the international standard G code generated by the software. |

Fiber Laser Source Brand: Maxphotonics |

| cutting head using raytools swiss brandFiber laser cutting dedicated cutting head to ensure high accuracy and efficiency for cutting. The cutting head is equipped with a non-contact capacitive sensing device. Can be achieved very stable Z-axis automatic tracking function, eliminating the influence of cutting due to asperous plate, and then improve the qualification rate of products. Laser cutting machine is equipped with focus lens , to meet the customers needs of cutting plate. Lens replacement using drawer type, the entire replacement process very convenient and fast. Optical system has the advantages of high efficiency, stability, calibration, maintenance and so on, the entire optical system is protected by clean positive air to ensure that the optical lens and nozzles are not contaminated. |

Application Industry

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Mainly used for cutting Mild steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminium zinc plate, copper and many kinds of metal materials and so on.