Product Details

Detailed Product Description

| Product Name: | High Precision Metal Fiber Laser Cutting Machine | Laser Power: | 500w/800w |

|---|---|---|---|

| Working Area: | 500*500mm | Max Moving Speed: | 60m/min |

| Positioning Accuracy: | ± 0.01-0.03 | Powe Supply: | 3×380V±10% 220V±10% |

| Package: | Wooden Case | Warranty: | 1 Year |

Precision laser cutting machine is designed and made by RISE LASER. Adopted with leading laser technology for thin sheet metal application. The machine is combined with marble and Cypcut laser cutting system. With Integrated designing, dual gantry linear motor driving system, friendly interface and long term stable working.

* Safety structure

* Less occupation, good for small workshop.

* Easy opertaion

* The leading cypcut cutting system, easy to be used.

* Anti-corrosion wear

* Free maintenance of transmission parts, corrosive material cutting is available.

* Stable and durable

* Marble machine tool, less distortion, high stability, anti-shock while high speed working.

* Precision cutting

* Best cutting comes from Switzerland RAYTOOLS laser cutting head

* Fiber lasers

* Adopted with top brand fiber lasers China made with good quality and stability.

* Precision motion mechanism

* Dual linear motor driving system can improve cutting accuracy and efficiency.

Configuration

| # | Item | Specification | Brand | Remark |

| 1 | Laser Source | 800W | Maxphotonics | |

| 2 | linear motor | Raytools | ||

| 3 | Optical grating | resolution 0.5μm | Spain | |

| 4 | Driver | servotronix | ||

| 5 | Z axis Screw module group | Empower | ||

| 6 | Laser cutting head | BT230 | Raytools | |

| 7 | Precision linear guide rail | Hiwin | ||

| 8 | Marble | 1800*1350*200 | Shandong | |

| 9 | Organ cover | Standard | Raytools | |

| 10 | Machining material | Standard | Raytools | aviation aluminum-alloy

|

Parameter

| Model | 5050 | |

| Working size | 500×500(mm) | |

| Max. Acceleration | 1.2g | |

|

X AXIS | Max. Moving speed | 60m/min |

| Route | 500mm | |

| Positioning accuracy | ±0.01mm | |

| Repeatition accuracy | ±0.004mm | |

|

Y AXIS | Max. Moving speed | 60m/min |

| Route | 500mm | |

| Positioning accuracy | ±0.01mm | |

| Repeatition accuracy | ±0.004mm | |

| Z AXIS | Route | 100mm |

Working condition

| 1 | Working temperature | -10℃~45℃ |

| 2 | Relativede Humidity | <90% no condenser |

| 3 | Environment | Good ventilation, no vibration |

| 4 | Power supply | 3×380V±10% 220V±10% |

| 5 | Power frequency | 50Hz |

Machine proposal

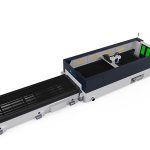

4.1 The Machine rack adopts marble structure and US CNC laser cutting system. With Integrated designing, through gantry milling machine processing ,so to make the movement be accurate .linear motor driving system, friendly interface and long term stable working.

Adopted THK Japan precision linear guide rail, with high accuracy, low abrasion and easy to be assembled or exchanged.

4. 2 laser cutting head

BT230 (Raytools, Switzerland brand ) laser cutting head with auto focus system. It can prevent materials waste from distortion cutting. The protection glass can keep and protect the low cost of the important optical parts inside of the cutting head. Auto focus system is suitable for non-flat metal sheet processing. Combined with high quality lasers the BT230 can be widely used in ceramic, medical, semiconductor and other industries.

| collimation | 100mm |

| focus | 125mm |

| optical aperture | 25mm |

| nozzel (single) | :0.8/1.0/1.5/2.0/2.5/3.0/3.5/4.0mm |

| lens materials | quartz |

| fiber plug | QBH |

| Auxiliary pressure | Max. 20bar |

| weight | ~1.5Kg |

4. 3 Control system

The use of professional PC industrial computer operation, graphical interface, easy to operate, professional cutting control software can freely design a variety of graphics and text, real-time processing, support CAD, CorelDraw and other professional mapping software.

. High-quality industrial computer control operation

. High efficient, easy to operate CNC cutting system

. Z axis automatic tracking function

CNC cutting control system

CNC cutting control system is the use of high-performance control card, based on Windows XP Professional development, fully docking with CNC control system, therefore, the real-time control and software upgrates between machine and laser source more convenient and fast.

Main features of control system

Stable operation,good anti-interference ability

Fast moving speed, smooth start and stop

Good cutting effect, fast cutting speed

Enhanced capacity for large data processing

Output control:support unified entity output mode, support any position to start cutting, combined with the NC and graphics two output modes, can be modified after the stop parameters.

Software

l English version available

l Saving processing files as requsted

l working motion and cutting state display

l Can support DXF, international G code NC files.

l Cutting Calculation automatically

l According to Processing needs,it supports to change the cutting start position and processing direction , meanwhile , the system dynamics will adjusting to guide in or guide out the line position .

Optimize working time when import the files or manual adjustment.

Partial data imported and applied from group is available

Automatic nesting software CAM

High response, high sampling rate, high transmission rate, guarantee the stability of servo system, through the system, a key can calibrate the sensor's working.

EtherCAT BUS CNC system (AheadTechs) can support the control flexible for more combination interface .Support to variety of modes of shaft pitch compensation to ensure the machining accuracy.

Management for processing parts statistics and production quantity.

Theory Cutting parameter

| Power(W) | Material | Thickness(mm) | Cutting speed(m/min) | Gas |

| 800 | Stainless steel | 1 | 8-9 | N2 |

| 2 | 5-6 | N2 | ||

| 3 | 1.8-2 | N2 | ||

| 4 | 1.2-1.3 | N2 | ||

| 800 | Carbon steel | 1 | 8-10 | O2 |

| 2 | 4-5 | O2 | ||

| 3 | 2.8-3 | O2 | ||

| 4 | 1.4-1.8 | O2 | ||

| 5 | 1.2-1.5 | O2 | ||

| 6 | 0.9-1.1 | O2 | ||

| 8 | 0.6-0.7 | O2 |