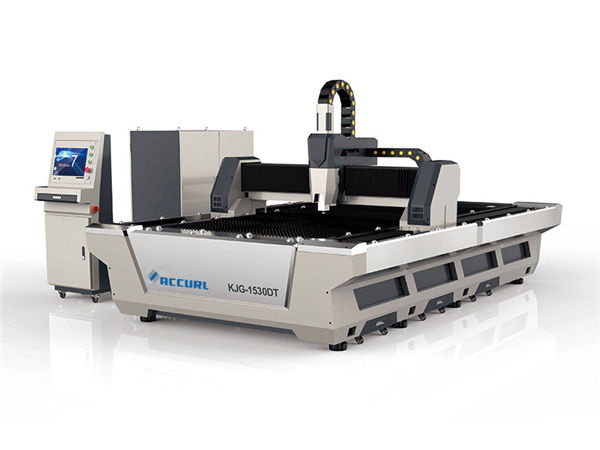

Product Details

Detailed Product Description

| Product Name: | Plate And Tubes Fiber Laser Cutting Machine | Laser Type: | Fiber Laser |

|---|---|---|---|

| Laser Power: | 800w/1000w/2000w/4000w | Warranty: | 12 Months |

| After-Sales Service: | Engineers Service Overseas | Weight: | 3000 Kgs |

| Control Software: | Cypcut | CNC Or Not: | YES |

| Applicable Material: | Metal Tube And Metal Plate | Power Supply: | AC380V±5% 50/60Hz (3 Phase) |

Products Description

Tube Laser Cutting Machine P2060A Main Features

Rise Laser tube laser cutting machine P2060A adopts most sophisticated fiber laser N-light / IPG, combining self-design Gantry CNC machine and high strength welding body. After high temperature annealing and precision machining by large CNC milling machine, it has good rigidity and stability with imported high precision and high speed, linear guide drive,high-speed servo motor.Aluminum beam, advanced heat treatment process, high strength, light weight, good rigidity. It is mainly for cutting tube under 20mm metal in high speed and high precision. Fiber laser has a series of advantages, such as high beam quality, high brightness, high conversion rates, maintenance-free, stable and reliable operation of low cost and small size, etc. Air-assisted cutting is the most advanced level of laser cutting, which is particularly suitable for stainless steel,carbon steel,alloy,brass,copper, titanium and other metal materials precision cutting. It is widely used in metal products,bicycle, metal furniture,fitness equipment,sports equipment,farm machinery,display shelf,fire control.

Machine Features

1. Design of double electric chucks and double servo motors, apply to cut tube as round ,square, Rectangular tube, oval tube, I-beam, etc.

2. Pneumatic rolling wheel supporting design to ensure the turning stability during cutting.

3. High-performance laser source and stable operating system that make the best cutting effect.

4. The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

5. The machine can be used for cutting a variety of metals with excellent and stable cutting quality.

6. With a specialized CAD / CAM automatic programming software and automatic nesting software, it is possible to maximally g save raw materials.

7. Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process.

Technical Parameters

Fiber laser power : 800W, 1000W, 1500W, 2000W, 3000W 4000W (Optional)

Working size : 3000*1500mm

X and Y positioning accuracy : +-0.05mm

Transmission mode : import Germany Atlanta high precision gear and rack with double driving rack fiber laser cutting machine

| Laser power | 800W 1000W 2000W 3000W |

| Laser source | IPG/N-LIGHT Maxphotonics fiber laser resonator |

| Pipe/Tube processing (Φ x L) | Φ=20-300mm, L=6m,8m,12m(Φ=20-300mm for option; L>6m for option) |

| Pipe/Tube category | Round, square, rectangular, oval, waist round, etc |

| Rotate speed | 120 turn/minute |

| CNC control | Cypcut / Germany PA HI8000 |

| Laser head | Switzerland Raytools |

| Power supply | AC380V±5% 50/60Hz (3 phase) |

| Total electric power | 22KW |

| Position accuracy | ±0.03mm/m |

| Repeat position accuracy | ±0.02mm |

| Maximum position speed | 70m/min |

| Acceleration | 1g |

| Drawing programming mode | Solidworks,Pro/e,UG, etc import directly |

| Machine weight | 6.5-7.5T |

Advantage of Fiber Laser Cutting Machine

1. Excellent path quality: Smaller laser dot and high work efficiency, high quality.

2. High cutting speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7. Easy operations: fiber line transmission, no adjustment of optical path.

Machine Details

Pipe Automatic Bundle Loader features

1.Automatic bundle loader for option which saves labor and loading time, achieve mass production purpose

2.Round pipe, rectangular pipe and other pipes can be fully automated loading, without human intervention.

3.Other shapes pipe can be semi-automatic feeding artificially.

4.Max Loading Bundle 800*800mm

5.Max Loading Bundle Weight 2500kg

6.The tape support frame for easy removal

7.Bundles of tubes lifting automatically

8.Automatic separation and automatic alignment

9.Robotic arm stuffing and feeding accurately

Automatic collecting device

1. Automatic elevating support, receive tube and scrap into the basket

2. Visual scale support can adjust support diameter quickly according to pipe diameter

3. Visual scale adjustable support lifting device saves feeding time, ensures concentricity, prevents pipe swinging

Lift adjustable support system

The cutting of pipes of different diameters, by adjustable support system to quickly and accurately find concentricity pipe and claw, to achieve rapid feeding, care feeding purposes, saving setup time cut-out.You can assist chuck support, reducing the swing pipe.

Integration bed

1.As a whole plate welded bed, the whole length of 8 meters.

2.Integration bed can better ensure concentricity of equipment, vertical, precision installation fast and efficient.

3.The whole structure is compact precision.

3D user interface

1. Intuitive interface, better compatibility with Solidworks, Pro / e, UG software, convenient and easy to operate.

2. radical departure from the traditional CNC operating software code programming style complex method of operation.

3. Reduce the operator's requirements.

Online diagnostic function

CypTube have received servo feedback function cutting head, laser and other components, is available online diagnose the failure point device.

Product Application

Application: It can cut pipe, squre tube, and various special-shaped pipe cutting.

Diameter for tube:20-200mm

Cutting length: 6m/4m etc

Cutting thickness with 500W fiber source: 3mm stainless steel, 6mm carbon steel, 2mm copper, 2mm aluminum etc, 2.5mm galvanised plate etc.